Automotive

Production in the automotive industry is characterised by high quantities and technically and economically demanding processes. The demand for low vehicle weight and high passive safety leads to a material mix that makes thermal joining processes increasingly difficult. Adhesives are playing an increasingly important role in body-in-white and final assembly. Special crash adhesives improve the crash behaviour compared to spot-welded structures. Attachment parts are joined together structurally or elastically and the vehicle is sealed at the same time.

Home » Formulated systems » Automotive

Glass bonding for automotive

Elastic adhesives are used for window pane bonding. High elasticity and low stiffness prevent the transition of stress peaks and thus tearing of the pane, e.g. in the case of twisted car bodies. High adhesive strength guarantees that the windscreen remains bonded to the body even in the event of a crash.

Joint sealing, joint filling & underbody protection for automotive

In addition to bonding, seam sealing is an important function of an adhesive and sealant. The penetration of water into gaps and cavities as well as the resulting corrosion are prevented. Depending on the application, different types of materials are used.

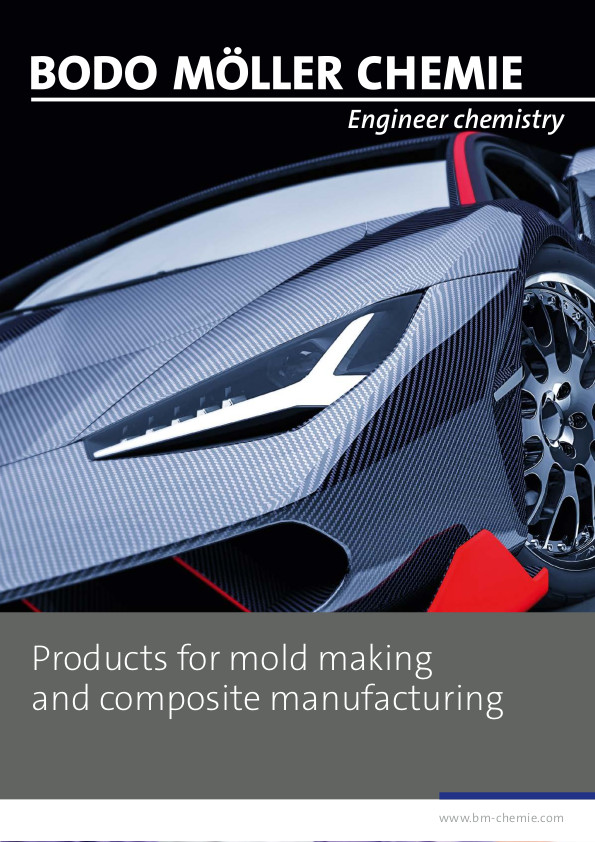

Modeling, mould making & prototype construction for automotive

In model and mould making, block materials are used from which tool and component geometries are milled. Modelling pastes are also used. As visual samples, components are often produced and reproduced by simple and inexpensive casting with casting resins.

Production of composite components for automotive

Carbon components are often used in sports car construction to reduce structural weight. CFRP components are usually manufactured with epoxy resins, which offer the best mechanical properties and thermal resistance.

Production of e-mobility components

Power electronics and battery systems must dissipate the resulting heat via the surface. This requires heat conducting materials. Electronic components are encapsulated with special resin systems and thus protected against external influences, housing components are joined with adhesives and sealed.

Structural bonding in the body construction for automotive

In body-in-white, the spot welding process is increasingly being replaced or supplemented by structural bonding. The advantages here are optimized crash behavior and improved corrosion protection. As a rule, adhesives are applied to the raw part and spot-welded to each other through the adhesive seam. The adhesive then hardens in the KTL furnace.

Structural bonding of exterior components & interior for automotive

A variety of different materials (e.g. plastics, composites, metals, glass) are used for add-on and interior parts. Special requirements arise from the combination of materials. The adhesive must build up good adhesion to the materials to be bonded, differences in thermal expansion are compensated by the adhesive and the adhesive joint.

Surface pretreatment for automotive

A clean and grease-free surface is necessary to ensure a high-strength, durable bond. Surfaces are treated with suitable cleaners. In some cases additional primers are used to increase the adhesive strength and long-term durability. Cleaners, primers and adhesives are matched to each other and the process reliability is proven.

Industries

Events

Seminar: Design and application of chemical products in electronics production

14.05.2024, Rapperswil-Jona

TechDialog: Adhesive technologies in industrial manufacturing

16.05.2024, Heidelberg

The Battery Show Europe 2024

18.06.2024 - 20.06.2024, Stuttgart

News

Bodo Möller Chemie obtains majority share in distribution company Losi Group and expands into aerospace market

JEC World: Bodo Möller Chemie presents technological innovations and an expert lecture during the trade fair.

Bodo Möller Chemie expands its collaboration with SONGWON and is now exclusive distributor for coating products in Germany.