Full service for all aspects of applied adhesive technology

Adhesive Laboratory - Testing of adhesive joints

In our modern and extensively equipped adhesive laboratory, we test all structural adhesive types according to ISO, EN and DVS standards for our customers. For this purpose, all the common adhesive test methods for determining the mechanical, thermal and structural properties of adhesives are available, such as the tensile shear test, track and angular peel tests, and aging simulations (e.g. Cataplasma, weathering). When selecting an adhesive, laboratory tests are used to determine whether an adhesive is suitable for the desired application, taking into account various factors such as the type of substrate, surface texture, application temperature and environmental conditions. Laboratory

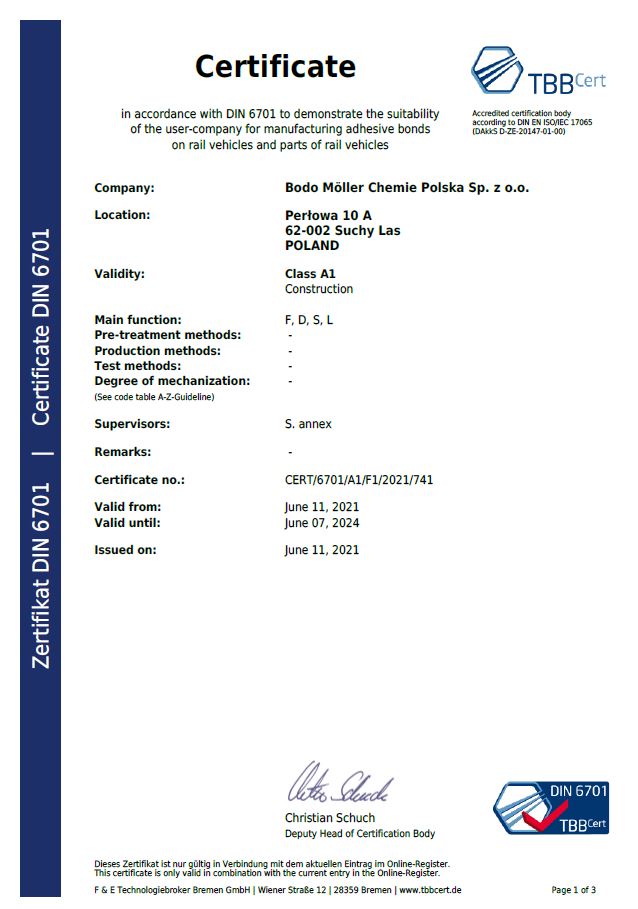

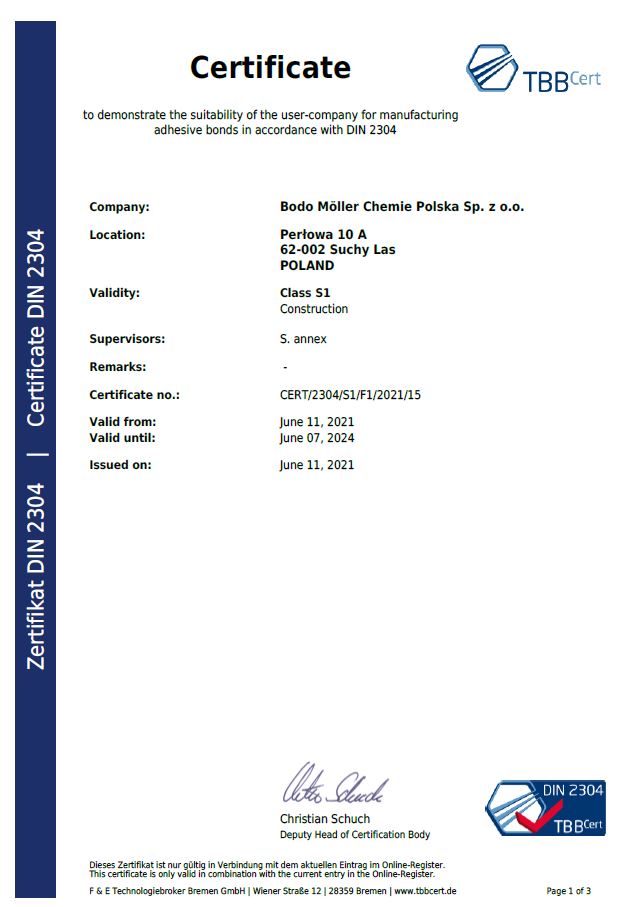

tests therefore make a decisive contribution in the quality assurance of adhesive-based connecting technology. Our laboratory is certified according to the highest safety class (A1/S1 level) according to DIN 6701-2 for the bonding of railway vehicles and vehicle parts and according to DIN 2304-1 for the calculation of adhesive bonds. More than 15 other certifications make us the competence center for adhesive applications in a number of relevant industries.

Engineering Data Management - Determination of construction data for calculating adhesive bonds

Frequently, the standard data of adhesives are not sufficient for engineers and technologists. It lacks the relevant technical data necessary to perform a comprehensive process simulation. We therefore convert key chemical characteristics into design data in our Adhesive Competence Center. Using laboratory tests, we determine the mechanical, thermal and structural properties of adhesives as the basis for the calculation of adhesive bonds. The technical data are obtained through elaborate long-term tests in our adhesive laboratory, which is certified in accordance with DIN 6701 and DIN 2304. This is a service which is unique throughout the world. With this data, adhesive engineers have an important tool to design high-quality and safe adhesive joints.

Design Office - Calculation of adhesive bonds

The adequate quality of the adhesive bond is for safety-related adhesive applications of crucial importance, particularly in the manufacture of passenger cars, trucks, buses and rail vehicles. As an expert for adhesive bonding, we offer our customers not only the determination of technical data of adhesives, but also the calculation of adhesive bonds as a service. We are certified according to the highest security class (A1/S1 level) according to DIN 6701-2 for the bonding of rail vehicles and vehicle parts and according to DIN 2304-1 for the calculation of

bonded joints. This guarantees extensive know-how and the highest quality. Based on laboratory test results, adhesive bonds are calculated using mathematical methods and FEM software (finite element method) and tested with the substrates of the customers. In this way, development processes can be significantly shortened and made safer and more efficient.

Audit Body - Preparation and implementation of pre-audits

The implementation of the standard DIN 6701 creates a high demand for standardisation and certification procedures in the railway industry. Similarly, this is to be expected for general industry according to DIN 2304. As a further service, we support companies in the preparation of audits according to DIN 6701 and 2304. Our qualified adhesive specialists help to design the bonding processes in companies in such a way that they meet the high requirements of the standards. By using pre-audits, we prepare companies for the certification carried out by TBBCert and TC-Kleben.

Training Center - Transfer of product and application knowledge

Only if the development of adhesive technology goes hand in hand with the transfer of know-how to the user, can innovation unfold to its true potential. Through our partnerships with technology leaders, such as BASF, Dow, DuPont, Henkel and Huntsman, as well as research facilities, such as the Fraunhofer IFAM, we know about the latest product developments and system solutions. Together with our many years of experience in the automotive, railway, aerospace and electronics industries, we are able to offer a unique knowledge about products

and applications. We see it as our responsibility to share this knowledge with users. For this reason, we organise seminars, workshops and practical laboratory trainings, where our adhesive specialists, as well as experts from industry, research, and the certification bodies pass on their expertise to the participants.

Bodo Möller Chemie Polska Sp. z o.o.

Przemysław Kuśmierek

+48 605 550 427

acc@bm-chemie.pl

Certificates

ISO 14001 Germany

Environmental management system.

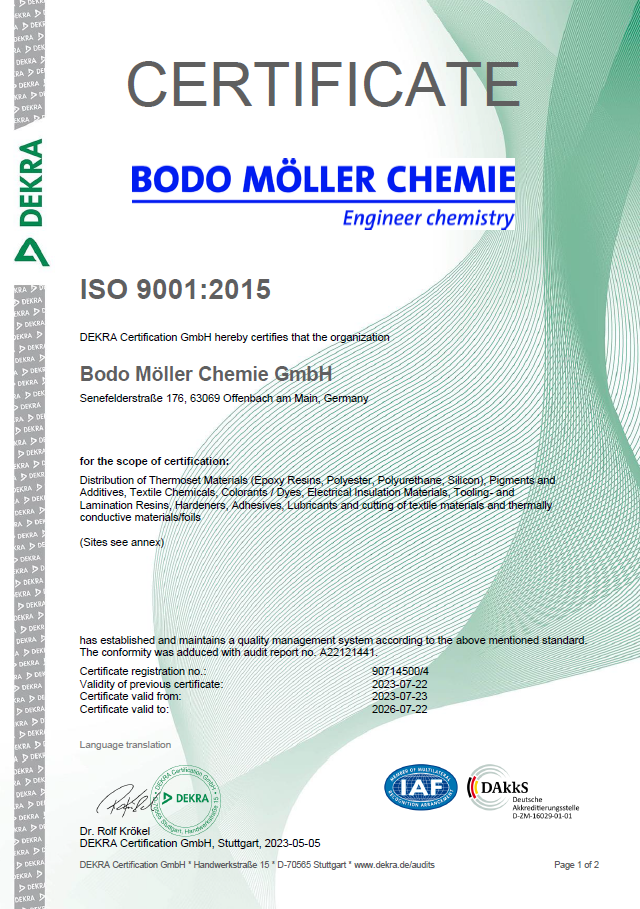

ISO 9001 Germany

DIN EN ISO 9001 refers to the merchandised service processes and to the internal processes of the organization.