Thermal Interface Materials

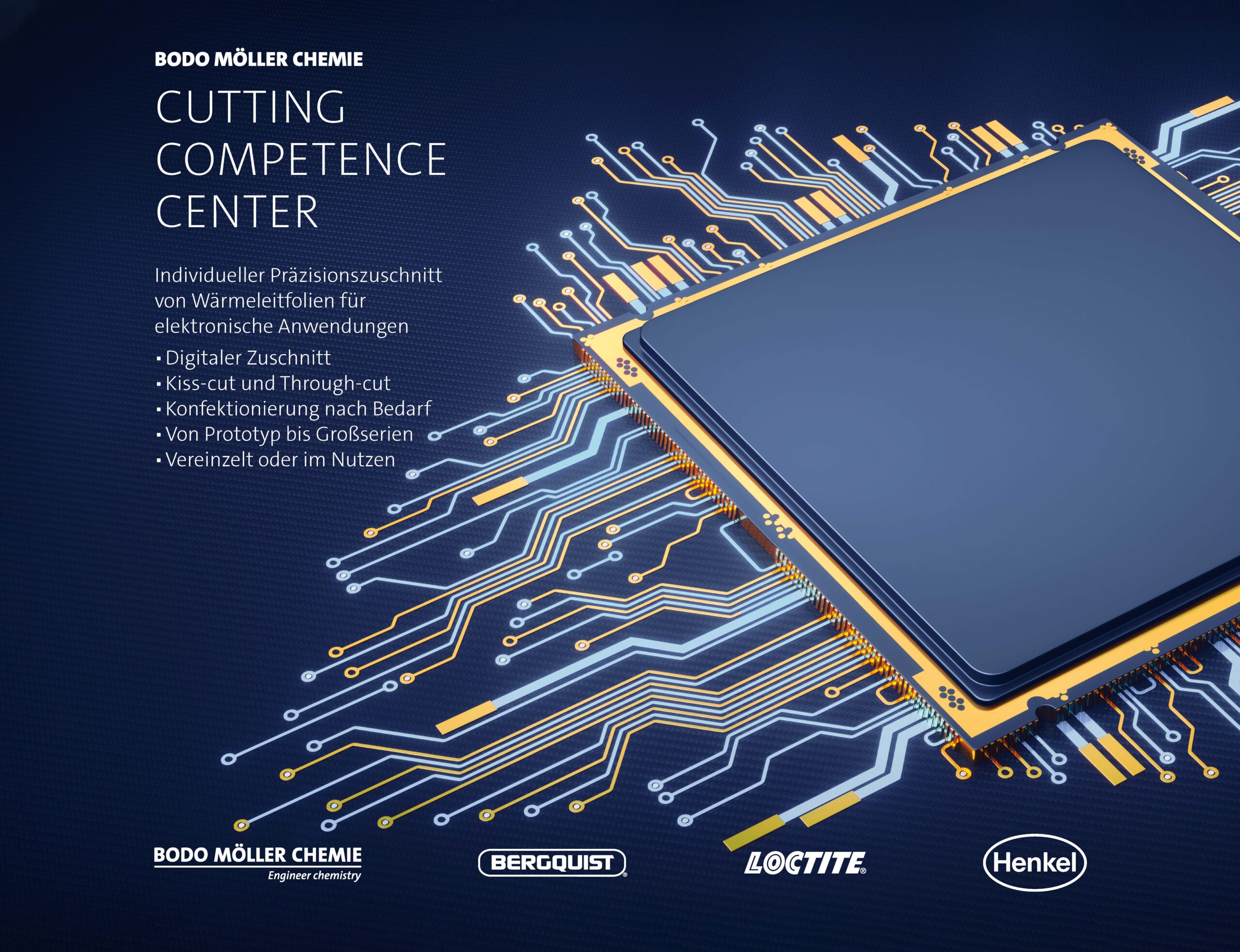

Bodo Möller Chemie offers the complete product family of thermally conductive materials for the electronic and electrical sector of Henkel Bergquist®. With the newly established Cutting Competence Center, we deliver highest quality digitally cut Bergquist® thermally conductive pads.

Bodo Möller Chemie is your expert for Thermal Interface Materials from Henkel.

Thermal interface materials are increasingly used in the electronics sector – in battery packs, electric drives, modern automotive light solutions, power electronics and they are equally needed by manufacturers and suppliers. Demand has grown enormously, above all in automotive and aviation, but also in many other sectors.

Contact our experts now

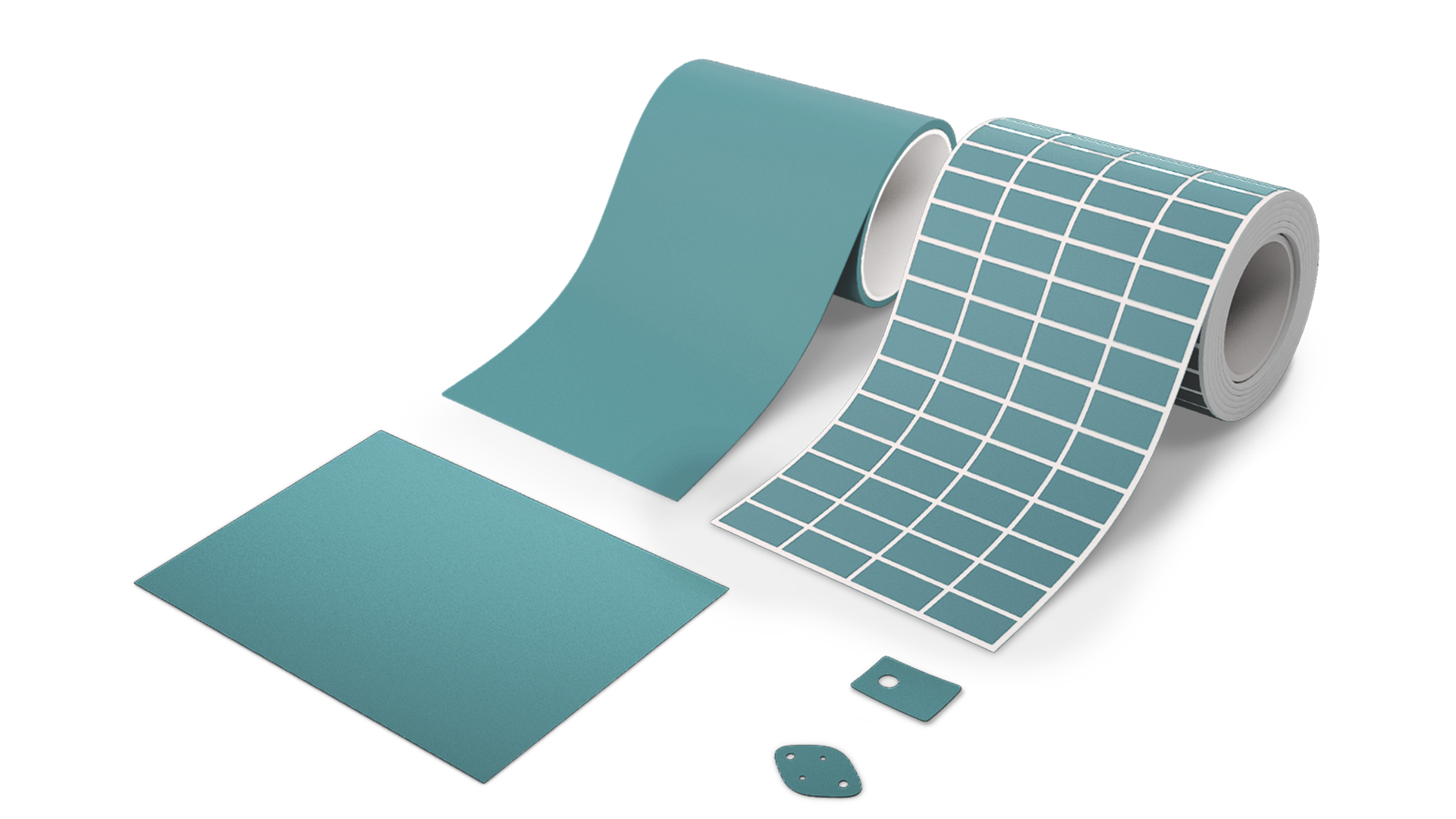

Cutting Competence Center: Delivering excellence on demand

With its newly established Cutting Competence Center, the Bodo Möller Chemie Group takes another step forward: Besides assisting our customers to select the best thermally conductive materials, we deliver highest quality digitally cut Bergquist® thermally conductive pads. With the Cutting Competence Center, located at Bodo Möller Chemie’s headquarter in Offenbach, we can digitally “kiss cut” or “through cut” thermally conductive materials in just one operation. To assure quality and precision to customer specification, the components are optically measured with a state-of-the-art measuring microscope after the cutting. This facility enables quick and efficient prototyping and small series production of TIM Bergquist® pads.

By establishing the Cutting Competence Center, the Bodo Möller Chemie Group offers a complete package of material selection, prototyping and series production ensuring highest quality for customers.

The perfect products for your application

Click on the pictures for more information

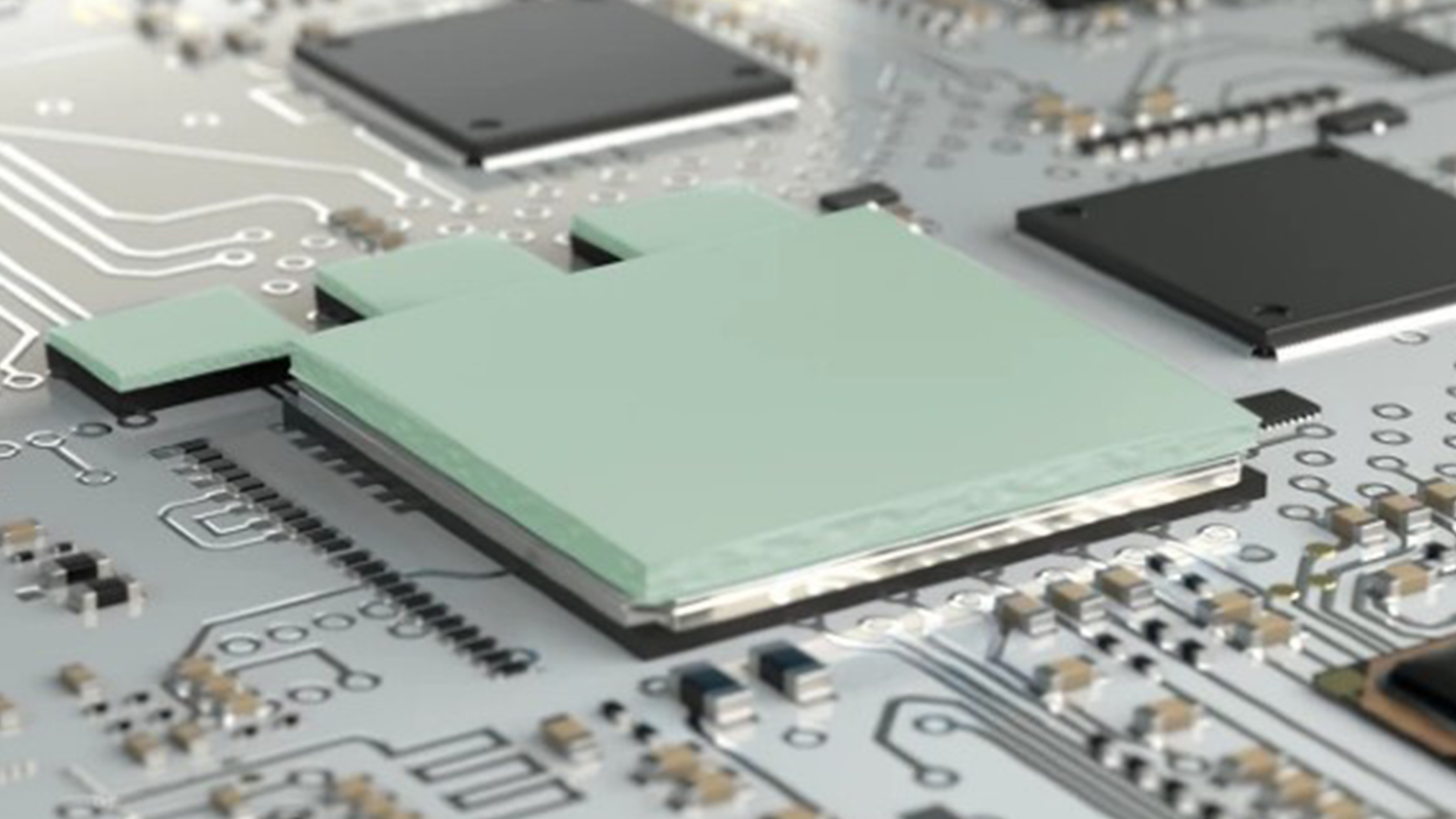

GAP PAD® Thermally Conductive Materials

GAP PAD® products from Henkel are soft, compliant thermal pads that provide effective thermal interface between heat sinks and electronic components, where uneven surfaces, air gaps and rough surface textures are present. These thermally conductive pads offer high conformability to reduce thermal resistance, even in large gaps.

In addition to effective heat dissipation, GAP PAD® materials also help to reduce vibration loads and absorb shock in a variety of applications.

Applications:

GAP PAD®s are well suited for a wide range of industries and applications. They are used in many types of assemblies in electronics, telecommunications, automotive, medical, aerospace, and satellites.

Bodo Möller Chemie recommends:

GAP PAD® TGP 1000VOUS (Ultrasoft)

GAP PAD® TGP HC 5000 (soft with high thermal conductivity)

Liquid Gap Fillers

Bergquist® Gap fillers are thermally conductive, liquid gap filling materials that improve thermal performance and allow easier dispensing for volume production. They are supplied as two-component systems that crosslink at room temperature. The gap fillers create a soft, thermally conductive form-in-place elastomer that is ideal for bonding heat-generating components to a metal housing or heat sink, resulting in maximum performance of the individual components and the device as a whole.

Applications:

Gap fillers are ideally suited for applications where pad configurations are not the first choice, and can be used to replace grease or potting compounds. They are currently used in many industries, including: power supply, telecommunications, automotive applications or electromagnetic Interface (EMI) shielding.

Bodo Möller Chemie recommends:

GAP Filler TGF 1500 (drip-free)

GAP Filler TGF 3600 (Very good thermal conductivity)

HI-FLOW Phase Change Interface Materials (PCM)

HI-FLOW phase change materials are an excellent replacement for thermal paste and serve as a high-performance thermal interface material between a CPU or other heat generative components and a heat sink. At room temperature, the films are solid and liquify as the board heats up. In doing so, they provide high reliability without a “pump out” effect.

Applications:

HI-FLOW materials are suited for consumer and industrial electronics, automotive, medical, aerospace and telecommunications applications such as:

- UPS and SMPS AC/DC, DC/DC or linear power supplies

- Between a CPU and heat sink

- Power conversion devices

- Fractional and integral motor control

- Leaded, surface mount and power module assemblies

Bodo Möller Chemie recommends:

HI-FLOW THF 1600P (good electrical insulation and robust)

HI-FLOW THF 3000UT (high thermal conductivity)

SIL PAD® Thermally Conductive Insulators

SIL PAD® thermally conductive insulators are a clean and efficient alternative to mica, ceramic or thermal paste and are used on a wide variety of components in the electronics industry.

Applications:

- Heat conduction between power transistors, processors or other heat-generating components and a heat sink or rail.

- Electrical insulation of components and power supplies from heat sinks and/or brackets

- Thermal interface for discrete semiconductors requiring low pressure clamp mounting

Bodo Möller Chemie recommends:

SIL PAD® TSP 1600S (Low thermal impedance)

SIL PAD® K1300 (durable, good cut-through properties)

BOND-PLY Adhesive Tapes

BOND-PLY materials are high performance, thermally conductive pressure sensitive adhesives. They are available in a PSA or laminating format and are used to replace thermosetting adhesives, screw and staple assembly. Repeated high continuous use temperatures increase adhesive strength. BOND-PLY are supplied in sheet, die-cut, roll and tabulated forms. Available in thickness range of 3 to 11 mils. Custom coated thickness.

Applications:

BOND-PLY adhesive tapes attach a heat sink to a graphics processing unit, power converter PCB or to a drive processor. They attach a heat spreader to a motor control PCB.

Bodo Möller Chemie recommends:

BOND-PLY TBP 850 (excellent dielectric barrier)

BOND-PLY TBP 400 (unreinforced for low energy materials)

LIQUI-BOND Liquid Adhesives

BERGQUIST® LIQUI-BOND liquid adhesives are high performance, thermally conductive, liquid adhesive materials. These form-in-place elastomers are ideal for coupling “hot” electronic components mounted on PC boards with an adjacent metal case or heat sink. High cohesive and adhesive strength and they cure to a low modulus.

Applications:

Automotive electronics, telecommunications, computers and peripherals and between any heat-generating semiconductor and a heat sink.

Bodo Möller Chemie recommends:

LIQUI-BOND TLB SA2000 (one-part material heat curing)

LIQUI-BOND TLB SA3500 (two-part material, room temperature storage)

Talk to our Experts

Your experts for Germany

Reno Wirnitzer

M +49 151 14824561

r.wirnitzer@bm-chemie.de

Rainer Fausel

M +49 151 18815644

r.fausel@bm-chemie.de