OUR PRODUCTS IN SWITZERLAND

Bodo Möller Chemie offers its customers in Switzerland solutions for automotive engineering, construction, plastics industry, electrical industry, aerospace, boat building, container and cabinet construction, wind industry, packaging industry, hygiene function and material protection for textiles and plastics.

The assortment of Bodo Möller Chemie in Switzerland ranges from adhesives, sealants, composite materials, resins, electronic casting & encapsulation, lubricant additives, adhesives for packaging and labeling and up to additives for hygiene and material protection.

Find your experts

Order online now

Adhesives & Composite Materials

Materials for Electronics

Surface Technologies

Mixers & Accessories

Our Partners in Switzerland

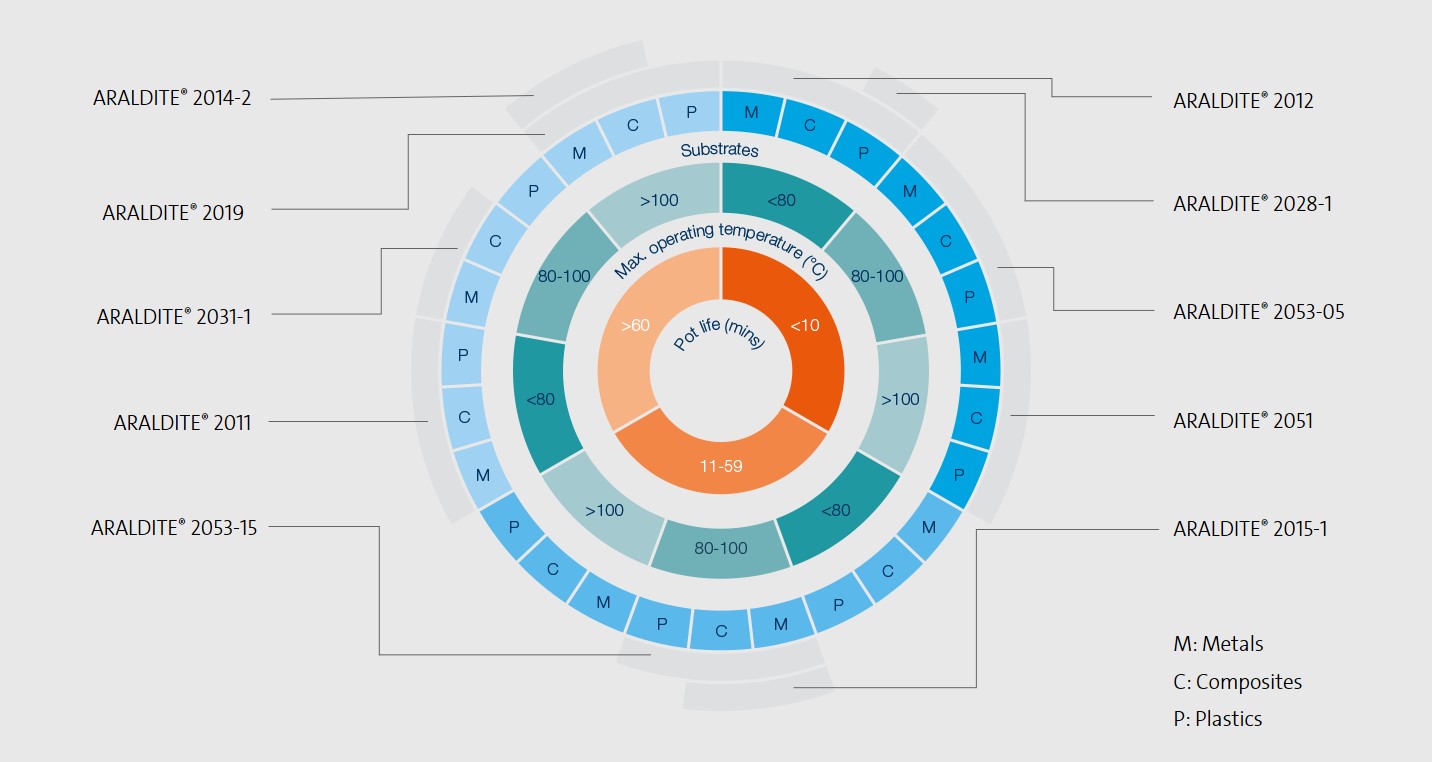

Adhesives for your industrial application

Adhesives are the core business of Bodo Möller Schweiz AG. In the company, trained chemists, adhesive engineers and adhesive specialists are exclusively responsible for this topic. Our aim is not just to sell individual products, but to provide advice based on our expertise in cross-linking chemistry, adhesive build-up processes and substrate properties in order to create a solution that will stand the test of time.

One of our most important brands is the traditional Swiss product Araldit / Araldite. Their core range gives you a good overview about the great portfolio.

Find out more detailed information on our page for adhesives and click here!

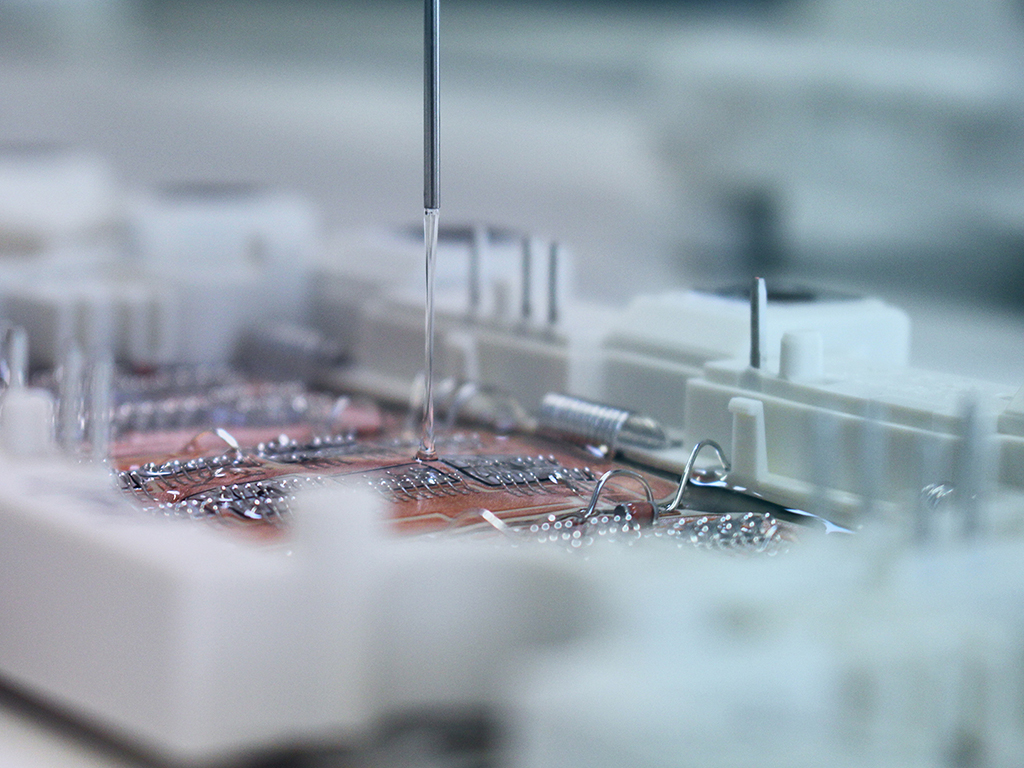

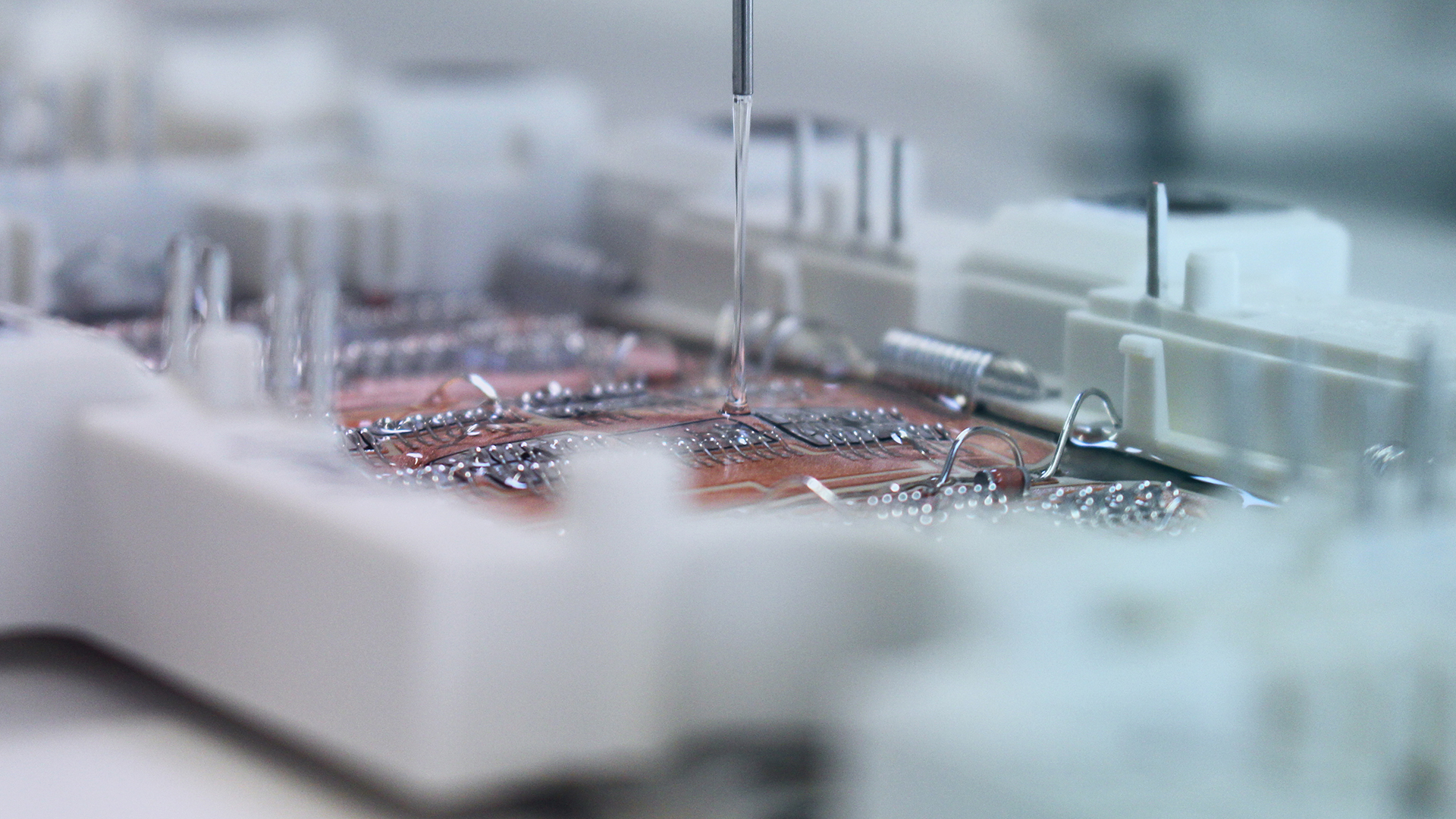

Casting Resins & Compounds

Bodo Möller Chemie Schweiz AG offers materials for the classic molding of components or assemblies, which are suitable for manual or system molding under atmospheric pressure, vacuum or in the pressure gelation process. Depending on the requirements, potting materials with thermosetting or elastomeric end properties on different chemical bases (polyurethanes, epoxy resins, silicones) and with different processing and curing properties are used. Furthermore, we offer solutions for electronic components.

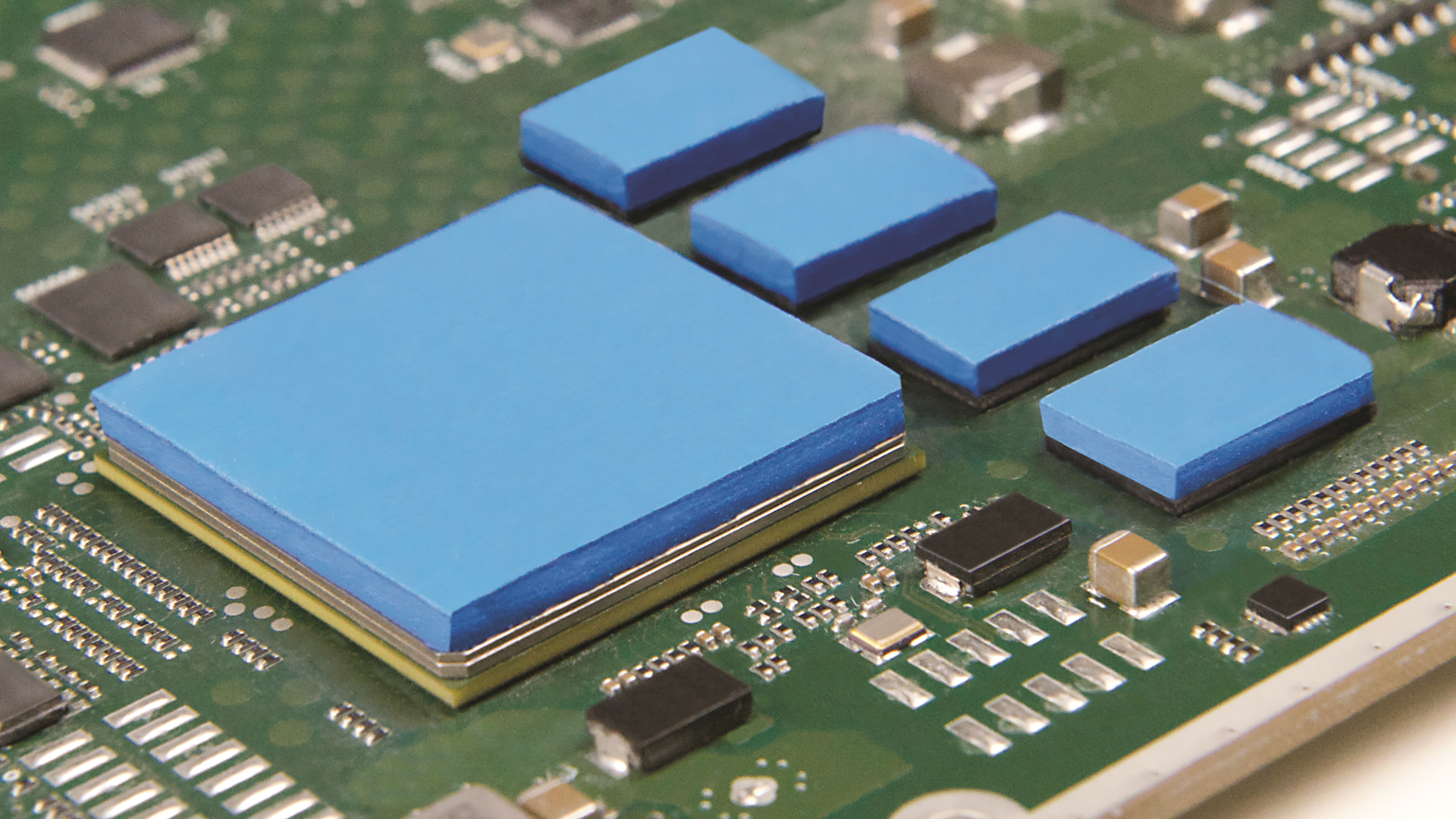

Thermal Interface Materials

TIM (Thermal Interface Materials)

Thermal and electrically conductive solutions from Henkel BERGUIST (high up to 5.5 W/mK – 8×10^-1 Ω∙cm).

Products Highlights

Liquid Gap Filler processable from cartridge

-> Bergquist GAP Filler TGF 3600

Fiberglass reinforced PAD up to 3.175mm

-> Bergquist GAP PAD TGP HC3000

Gel-like PAD for gaps up to 6.35mm

Best in Class -> Sil Pad TSP 1800

Potting systems

Potting systems for easy processing at room temperature and not necessarily with dispensing equipment. Systems also available in small containers.

Product Highlights

Best in Class PUR System CW5620/HY5610

Unfilled Epoxy System

-> Araldite DBF / HY 956

Flexible Epoxy System with UL94 (Yellow Card)

-> CW2243-2L/HY842

Highly filled epoxy system for high requirements

-> CW1302/HY1300

Temp- Class H (180deg) system

-> XB2252/XB2253

Insulation values for high voltage

Systems for highest demands on property values e.g. insulation values for high voltage

Product Highlights

Anhydride based system with high TG and low coefficient of expansion

-> CW229-3/HW229-1

1-component solution with up to 3.0 W/mK thermal conductivity

-> Aratherm CW 2731

Silicone potting compounds

Silicone potting compounds when temperature resistance above 200 degrees or low Shore hardnesses are required.

Hotmelt adhesives for the packaging industry

Bodo Möller Chemie Schweiz is pursuing its commitment to the packaging market with hot-melt adhesives and dispersions with a great deal of energy. As a premium partner of Henkel, we work closely with the application laboratory and also use our proximity to the machine manufacturers. (e.g. Robatech and Nordson). Here, too, Bodo Möller Chemie’s focus in Switzerland is on the customer and the added value we can offer through the right product advice.

We are happy to present our top products for your industry:

Core systems for end-of-line packaging applications

Temperature range Setting time Viscosity

Technomelt Supra Cool 120 120 -140˚C short 1200-1500 mPa’s

low temperature

Technomelt Supra 100 160 -190˚C short 1200-1600 mPa’s

universally usable

Technomelt Supra 120 140 -180˚C very short 450 – 800 mPa’s

fast setting

Technomelt Supra 150 Plus 160 -190˚C very short 1900 – 2500 mPa’s

increased requirement

Technomelt Supra 350 160 -190˚C short 1800-2600 mPa’s

for difficult surfaces

Data sheets: Supra 120 Cool | Supra 100 | Supra 120 | Supra 150 Plus | Supra 350

Technology Focus and product highlight

TECHNOMELT SUPRA PS: Especially for pallet securing

Reduce your material costs by up to 80% by switching from films to sprayable hotmelt for securing your pallets.

Technomelt Supra 7220-21 PS

150-180 ˚C | PSA | 4000 – 6000 mPa’s

Plastic additives & pigments

Plastics achieve their technical and optical properties through the use of additives and pigments during processing. Requirements such as durability, appearance, haptics, flammability, etc. are largely determined by additives and pigments. Through a professional selection of the correct additives, each plastic component can be given its individual performance.

Sanitized® additives for textiles, polymers and coatings

- With Sanitized® additives, polymers can be permanently protected against bacterial, algal or fungal attack.

- Increases the service life of the product (e.g. foamed PVC, PUR foams).

- Odor formation is prevented

- Users are protected against infections. (E.g. hospital equipment)

- Also an effect against SARS COV2 possible

Plastic additives

- Antioxidants

- Antistatics

- Flame retardants

- Hydrophilizing agents

- Light stabilizers

- Nucleating agents

- Optical brighteners

- Process and heat stabilizers

- Styrene-butadiene block copolymers (SBS)

Merck effect pigments

- Biflair®

- Candurin®

- Colorstream®

- Iriodin®

- Meoxal®

- Miraval®

- Pyrisma®

- Spectraval™

- Thermaval™

- Xirallic®

- Xirallic® NXT

Composite and Tooling

Our Composites product range includes high-quality, formulated epoxy resin matrix systems for the production of fiber-reinforced plastics for composite component manufacturing and mold making. The Composites product range covers all common manufacturing processes in industries such as automotive, bus, truck, rail, aerospace, wind energy, marine, and sports and leisure. Our Ureol Tooling Boards cover the entire range of model, tool and mold making.

Composite textiles – Porcher Industries

Porcher is a leading manufacturer of innovative textiles for all composite areas. The product range, driven by the will to innovate, impresses with its quality and market-oriented developments.

E-glass fibres | Carbon fibres | PrePregs

Here you will find an overview of all types and available finishes

Composite selector guide from Porcher

Composite Harzsysteme von Huntsman

The wide range of high quality resins and hardeners allows the production of high quality carbon fibre, aramid or glass fibre composite parts.

Our resin systems are suitable for all manufacturing technologies, such as wet lay up, infusion, pultrusion, RTM, high pressure RTM, filament winding, compression moulding and dynamic fluid compression moulding.

For more information, please download the brochure

Moldmaking systems from OBO and UREOL

With the liquid systems for mould construction from OBO-Werke, you will find the right solution for your project.

Laminating resins & pastes | Gel coats | Rapid casting resins | Release agents

Find out more:

OBO brochure

For more information, please download the brochure

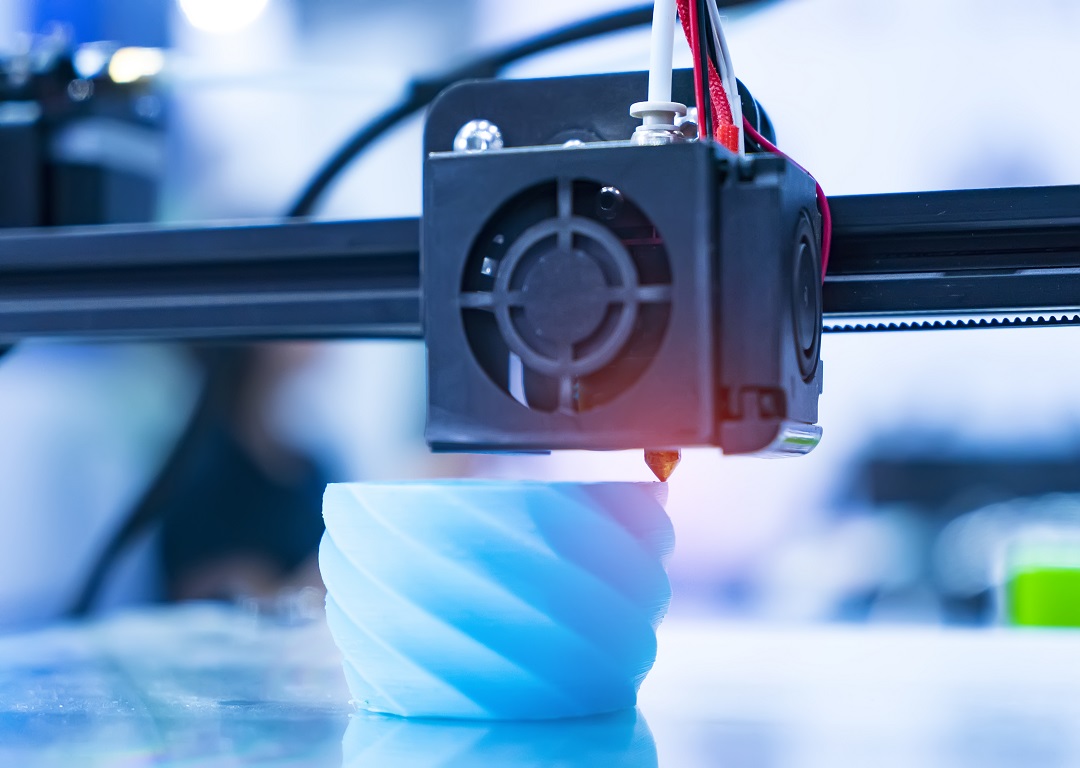

We bring 3D printing to Switzerland

Bodo Möller Chemie as a full-service DLP provider, bundles innovative 3D printing technologies from industry-leading suppliers under one roof and offers industrial users an attractive total package of consulting, engineering services, functional resins, DLP printing systems and printing services. The high-performance 3D printing materials and 3D printing systems guarantee the highest quality and productivity and are suitable for industrial-scale additive manufacturing in a wide range of industries, such as aerospace, automotive and transportation, consumer goods and medical technology.

For more information, please download the brochure

Additive manufacturing solutions for industrial production

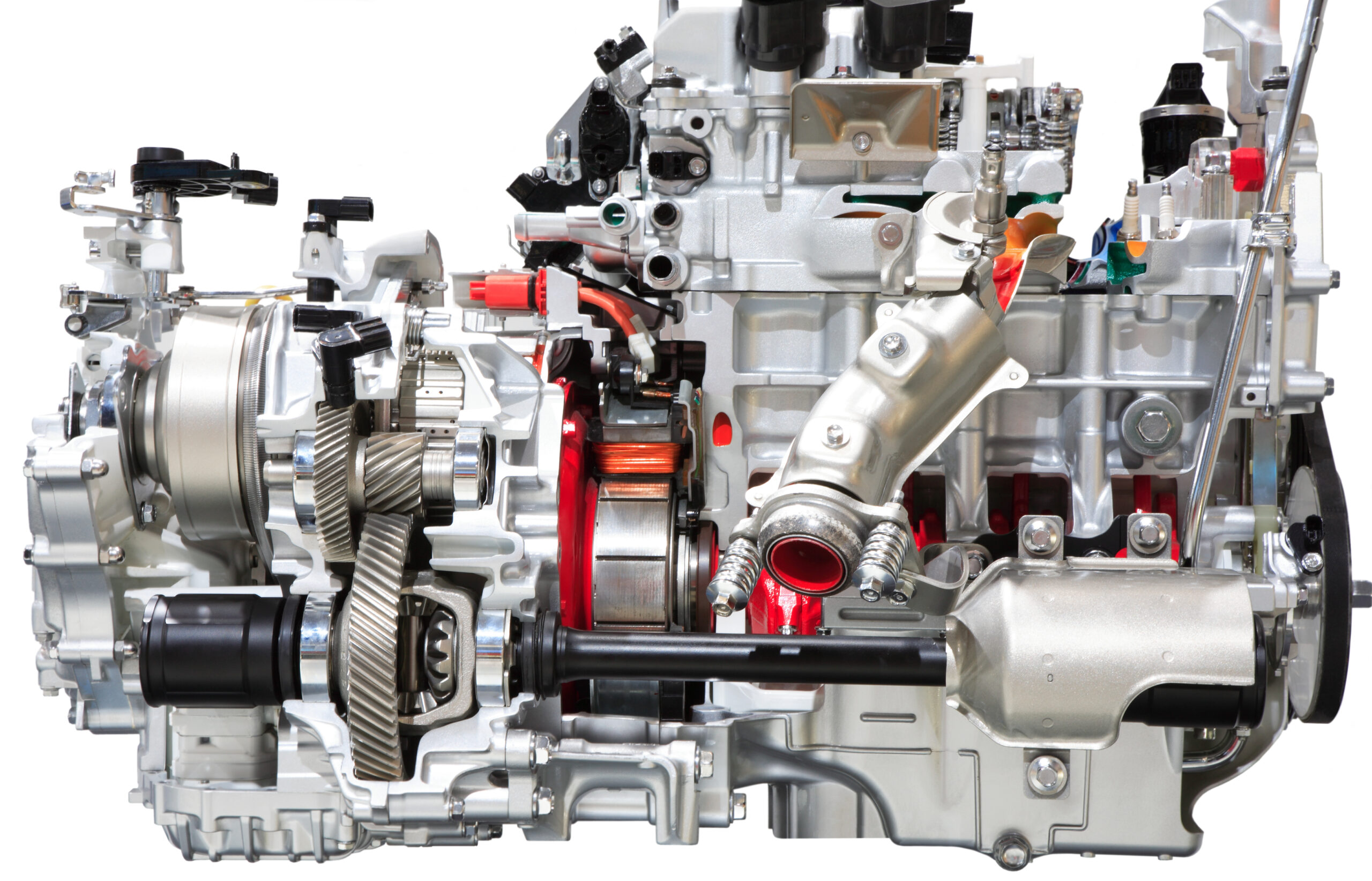

Maintenance Products

In the maintenance process of capital goods, time is one of the most important factors. It is therefore all the more important to select the right chemical agent. For example, selecting an efficient cleaner from Bonderite can save up to 20% time when steaming down chassis before disassembling components. In assembly, you must be able to rely on proven products that are designed for a wide range of applications.

For the automotive industry, we provide:

Assembly

We recommend the products Loctite 5188 for sealing gearbox housings and Loctite 243 for screw locking of components, both from Henkel.

For the insertion of washers we use BETASEAL 1580 from DuPont and for structural bonding Huntsman Araldite Epoxy 2014-2.

The PUR potting compound Araldite CW5620/HY5610 is ideally suited for protecting exposed electrical components. The Teroson MS 9360 sealant from Henkel is suitable for vehicle interiors, and for attaching radio equipment: 3M Dual-Lock adhesive tape.

Cleaner

Our products from Henkel are suitable for vehicle interior (BONDERITE C-MS 3100) and exterior cleaning (BONDERITE C-MC 12300).

Underbody cleaning (BONDERITE C-MC CS) and the cleaning of components (Loctite SF 7840) after removal are also covered by Henkel products

Contact our Swiss experts!

Philipp Capol

“My name is Philipp Capol and I am your contact for electro potting compounds | adhesives | composites & tooling materials.”

Jérémie Navarro

„My name is Jérémie Navarro, French and English speaking, I am your contact for adhesives, electro potting compounds, composites & tooling material”

Bodo Möller Chemie Schweiz AG

Rychenbergstrasse 67

8400 Winterthur

Schweiz

+41 52 2031930

+41 52 2031931

info@bm-chemie.ch