Adhesives

By definition, an adhesive is a non-metallic material which, via adhesion (surface adhesion) and cohesion (internal strength), creates a bond between two substrates. The bonding process is becoming increasingly important in all branches of industry every year. In addition to its main purpose, power transmission, each adhesive also has a certain sealing effect and vice versa.

Acrylic adhesives

Acrylic adhesives are two-part adhesives that provide excellent bond strength and durability. Acrylates adhesives have numerous advantages, these include very fast cure speed, high tolerance to slightly oily or unprepared bonding surfaces, and the ability to bond a wide variety of materials, including almost all plastics. Newer acrylic adhesive formulations are stable at room temperature and long lasting.

Adhesive films

Adhesive films are reactive materials that are usually supplied deep-frozen as roll goods. They are primarily used for bonding metal and composite components and for honeycomb sandwich structures.

Anaerobic adhesives

Anaerobic adhesives are used in applications with self-supporting or closely bonded metallic components such as ball bearing locks, screw locks, flange seals, surface seals and in sealing pipelines. Depending on the application requirements, adhesives are available for removable or permanent connections.

Cyanoacrylates

Cyanoacrylate adhesives offer a variety of positive properties, such as the bonding of different and difficult to bond materials, rapid curing with very high adhesive strength and a range of different viscosities. Cyanoacrylate adhesives thus offer versatile possibilities for the most demanding applications.

Double-sided adhesive tapes

Double-sided adhesive tapes are coated on both sides with a pressure-sensitive adhesive. Double-sided adhesive tapes can be used to join materials without visible fastening solutions by having the tape adhere the surfaces together. The intermediate supports of the adhesive tapes can be tenths of a millimeter thin foil, but also thick foam, which can be used to dampen vibrations. There are double-sided adhesive tapes that allow easy re-release and adhesive tapes that are suitable for permanent connections.

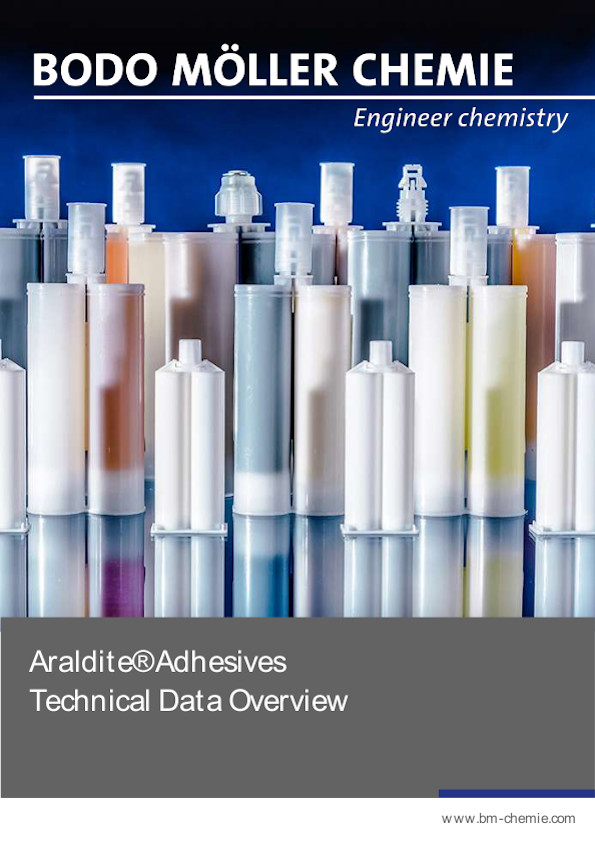

Epoxy resin adhesives (EP)

The most important group of reaction adhesives are epoxy resin adhesives. They harden with the addition of a hardener component without splitting off a low-molecular product and are addition-curing. Epoxy resin adhesives cover a wide range of processing and properties. The polymers are strongly cross-linked (duromers) and can achieve high strengths.

Hotmelts & packaging adhesives

The packaging industry made many demands on the adhesive bonding Food contact according to FDA, BFR.

Hybrid adhesives & sealants

Hybrid adhesives and sealants are silane-terminated polymers that combine the positive properties of polyurethane and silicone for use and processing, but chemically differs significantly from silicone. They have properties of the main chain comparable to those of polyurethane and harden like alkoxyl-curing silicones by elimination of methanol, but are free of silicone oils.

Methyl methacrylate adhesives (MMA)

Methyl methacrylate adhesives are polymerisation adhesives which harden by radical polymerisation and, depending on the formulation, can exhibit a wide variety of properties and strengths on a wide variety of materials. They are characterized by a very good ratio of open time to curing time.

Phenolic resins & polycondensation adhesives

In the case of polycondensation adhesives, polymerization takes place through the reaction of resin and hardener with the elimination of a simple molecule such as water, alcohol or acid. Phenolic resin adhesives have high strength values and very good temperature resistance. They are frequently used for bonding brake and clutch linings.

Polyurethane structural adhesives (PUR)

Polyurethane adhesives are also part of the group of reactive adhesives and also addition-curing. The polymers offer a range of properties from low crosslinked (elastomers with high elongation at break) to strongly crosslinked (duromers). The use of polyurethane adhesives is virtually unlimited, depending on the pre-treatment of the substrates.

Products for pretreatment & posttreatment of adhesive surfaces

The basis of a functioning adhesive bond is the optimal preparation of the adhesive surfaces. This includes the removal of adhesion-reducing layers, the increase of wettability and the preservation of the surfaces unitl bonding, in order to improve adhesion and increase resistance to ageing. To achieve this, cleaners, activators and primers are available as part of a complete system.

Sealants

Sealants are cold and hot crosslinking systems based on a wide variety of chemical compounds with permanently high elasticity and a broad adhesion spectrum on numerous parts to be joined. They are suitable for sealing seams, filling gaps and reducing vibrations in order to increase driving comfort.

Silicone adhesives & high temperature silicones

Ready-to-use silicone adhesives and sealants can be formulated in 1- and 2-component form and usually cure due to air humidity. Our products are specially tailored to the needs of the electronics, automotive and solar industries, as well as gastronomy technology and mechanical engineering. They are ideal for flexible sealing and bonding with high thermal and chemical resistance, non-sagging or self-levelling and adhere to a wide range of materials. In addition, we offer special products that can be used in contact with food or have UL 94 certification.

Spray adhesives

Spray adhesives are a fast, effective alternative to solvent-based adhesives for bonding most foams, fabrics, plastics, wood and light metals. Applications range from furniture upholstery, foam inserts, modular office panels to flooring and more. Spray adhesives are easy to use, are applied without additional tools, and are especially suited for bonding large surfaces.

UV curing adhesives

UV adhesives are 1-component adhesives that are suitable for a variety of substrates. They harden in a matter of seconds under the influence of UV light. They are ideal for joining glass to glass or glass to metal and can be used for a large number of plastics, as most plastics are also offered as UV-transparent.