Henkel Electronic Adhesives

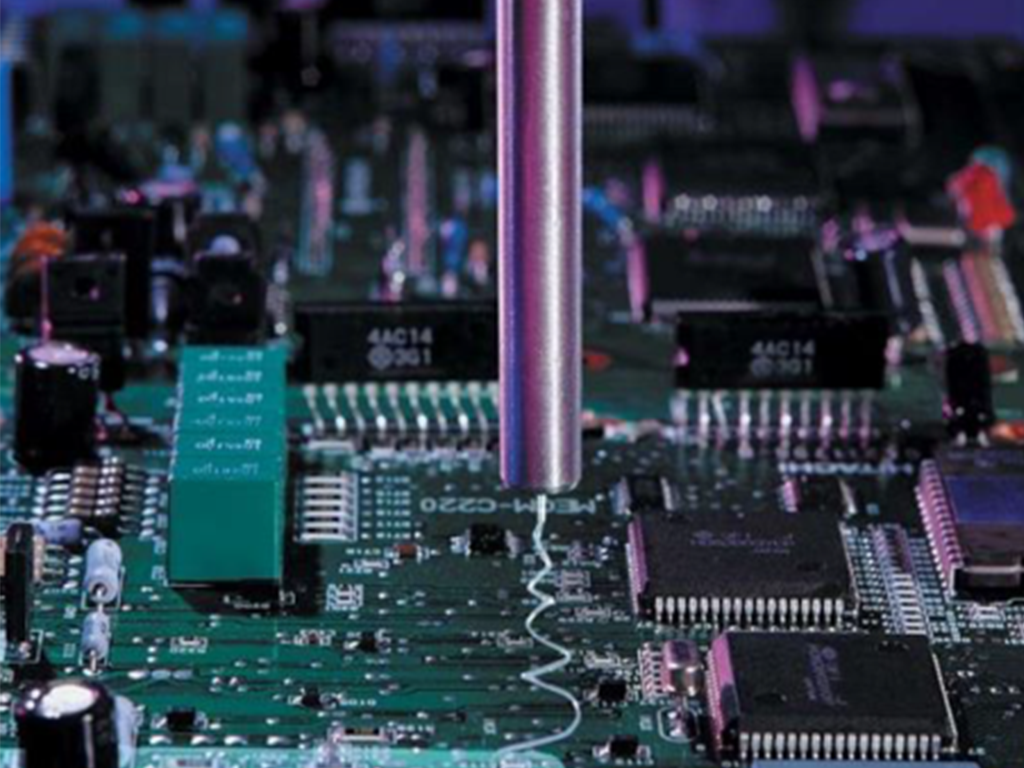

Our portfolio of advanced formulations includes a wide range of products to make electrical connections, enable structural stability, protect components and dissipate heat – for reliable, high-performance electronics today and further innovations and advances tomorrow.

Bodo Möller Chemie is your expert for Henkel electronic adhesives.

Electronic innovations are affecting almost every facet of our lives. We drive hybrid and electric cars with advanced driver assistance systems, use smartphones for work and leisure, immerse ourselves in new worlds with augmented reality (AR) headsets, enjoy personalized entertainment on airplanes and control our homes via networked devices.

Let's get in contact with our experts

Get Henkel products online

Download Brochures

Henkel Adhesives Selector

The Henkel Adhesives Selector helps you to identify the right adhesive product. It’s a 24/7 fast self service for requesting a sample and documentation access. A step-by-step solution analog a good personal consultation with our Experts.

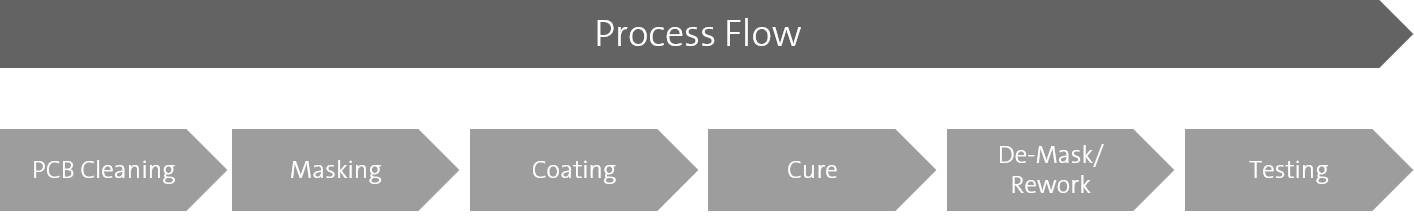

Conformal Coatings

Cornformal coatings are used to protect electronical components from environmental factors such as moisture, dust, chemicals and temperature fluctuations.

Henkel’s Conformal Coatings protect printed circuit boards and substrates from thermal shock, humidity, corrosive liquids and other adverse environmental conditions, ensuring long product life cycles for exposed applications in the marine, automotive, medical and consumer electronics markets.

With exceptionally fast cure capability and 100% solvent-free formulations, Henkel’s Conformal Coatings offer fast processing and are environmentally conscious.

Benefits of Henkel Conformal Coatings

- Solvent free system

- Use at high temperatures and adverse environmental conditions

- Wide range of curing options (UV, temperature, humidity)

- Complete protection against chemical and corrosive agents.

Our recommendation

- Loctite Stycast PC 88 (Fast drying, toluene free)

- Loctite 5293 (VOC compliant, hight Temperature resistance)

- Loctite Stycast UV7993 ( 100% VOC free, UV curable)

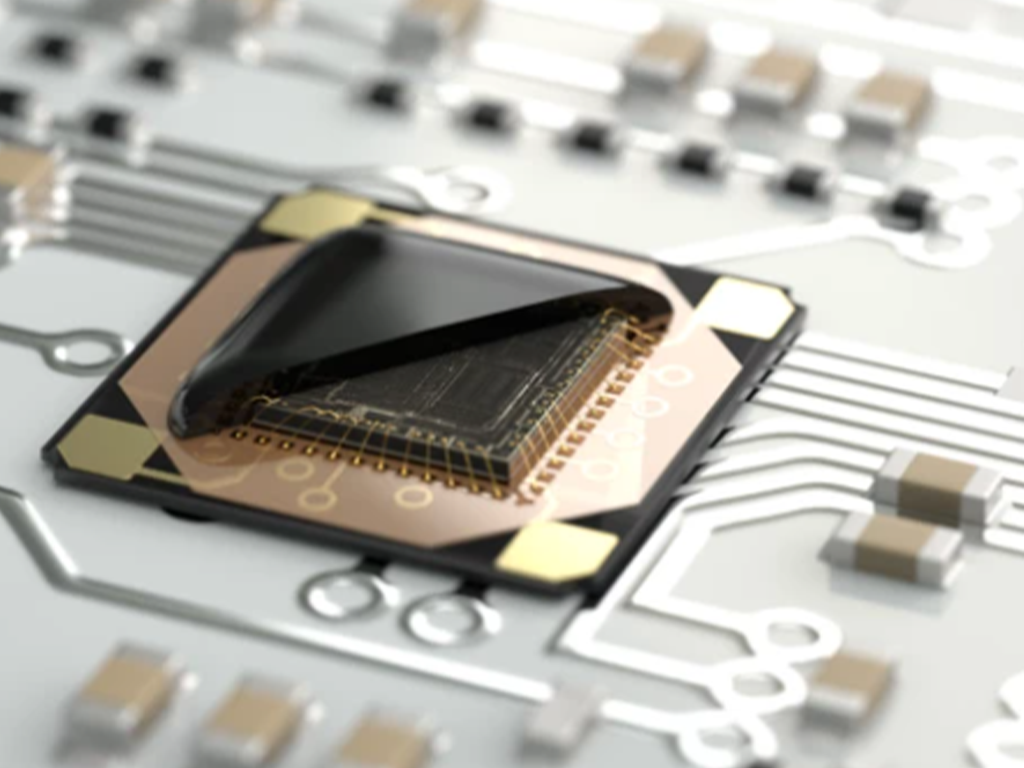

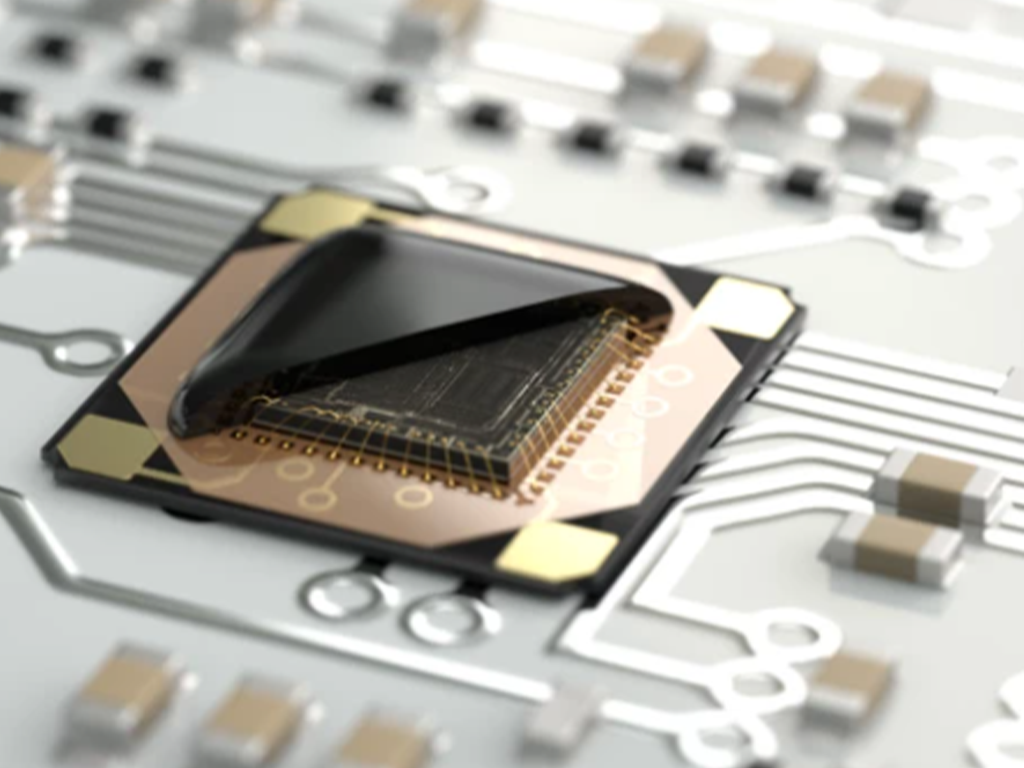

Chip on board (COB) Encapsulants

Henkel’s LOCTITE® and LOCTITE ECCOBOND-COB encapsulation compounds are primarily used to provide protection from external influences and to increase the mechanical strength of wired components.

Henkel’s high-purity encapsulants provide unmatched performance for a wide range of products, including transistors, system-in-package (SIP) devices, ASICs and chip-on-board applications. Cycle time and cost can be reduced by using LOCTITE ECCOBOND Glob Tops. These materials for chip-on-board applications are designed to cure quickly and can be easily implemented in high-speed manufacturing operations.

Benefits of Henkel COB encapsulations:

- Protection of particularly sensitive components against scratching or chemical exposure

- CMR/SVHC free products

- Excellent mechanical and chemical stability

- Good adhesion

- Fast cure / Snapcure systems

- Material mechanics from flexible to hard

Our recommendation

- DAM / FILL

- ECCOBOND 7010C DAM/FIL (CMR/SVHC free)

- Glob Top

- ECCOBOND FP4460 (Thermal Cure)

- ECCOBOND UV 9052 (UV Cure)

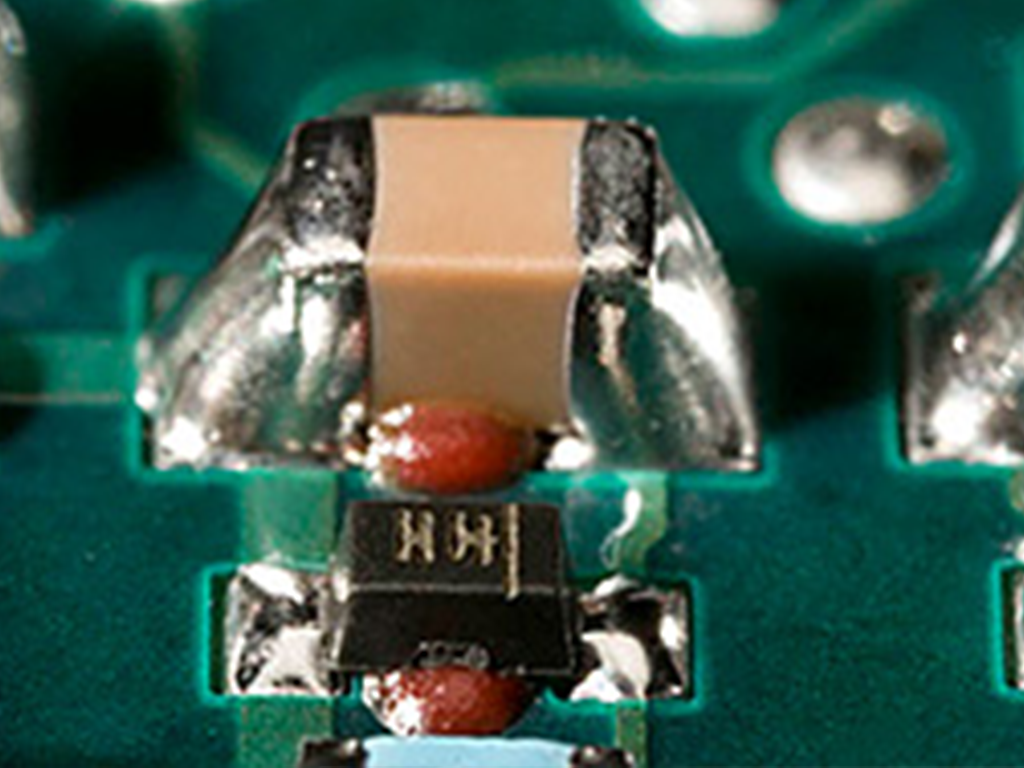

Underfill Materials

Underfill materials are used to mechanically reinforce the solder joints that connect an electronic component to a printed circuit board. The material reinforces the component by capillary action on the board. This helps prevent mechanical fatigue and extends the life of the board. Underfill materials are used to manufacture sensitive electronic housings for the automotive and electronics industries, among others.

Henkel has developed a range of underfill materials, each offering a specific property requirement. These materials have been specifically developed to provide manufacturers with a reliable and high quality product. Using Henkel underfill solutions in the manufacture of CSPs, BGAs, WLCSPs and other components can improve the performance and durability of a manufacturer’s products.

LOCTITE ECCOBOND UF3811/UF 3831

Relatively high Tg and improved TC under service conditions p to 100-120°C.

LOCTITE ECCOBOND E1216M

Excellent flowability with lower CTE and higher Tg than recyclable UF.

Without reportable REACH SVHCs and not CMR classified

LOCTITE ECCOBOND FP4531/E1172A / UF1173

Fast cure, very high Tg and very low CTE for highest thermal reliability

Contact our experts

Are you interested in our products or do you have questions about applications? Our specialists will be happy to advise you

Bodo Möller Chemie Online Shop

In our online store you can directly order the broad range of Henkel adhesives, materials for electronics production and surface technologies.

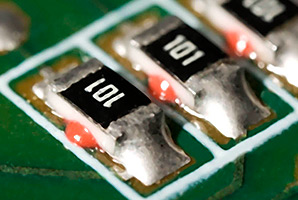

Electrically conductive adhesives

Henkel’s electrically conductive LOCTITE® adhesives ensure strong bonds between components and printed circuit boards – for reliable, long-term performance that meets demand. A broad product portfolio of ECA adhesives based on different raw material platforms, e.g. acrylates, epoxies and silicones, offers manufacturers a wide choice and flexibility for different application requirements, as hybrid systems are also possible.

Cost savings

- ECAs that use alternative filler technology or partially replace Ag to control cost structure without compromising ECA performance

- ECAs with corrosion protection technology that enable the use of 100% Sn-terminated components

- Flexible ECAs with low temperature cure profile reduce energy consumption in production

Environmentally friendly technology

- Low cure temperature ECAs enable the use of temperature-sensitive components and substrates

- Low temperature ECAs enable lower energy consumption

Enhanced reliability

- ECAs that meet the increasing reliability requirements of the industry

- ECAs with high current capability and heat dissipation

- ECAs with higher operating temperatures

Miniaturization, 3D integration

- ECAs for 3DMID electronics with focus on dispensing and printing small dots and reliable performance on non-precious (Sn,…) components with finish remove

Our recommendation

- LOCTITE ABLESTIK 84-1 LMI (Rigid Ag Epoxy)

- LOCTITE ABLESTIK CE 8500 (Rigid Ag Epoxy/Silikon, high temperatures)

- LOCTITE ABLESTIK CE 3520-3 (low cost Ni filler)

- LOCTITE ABLESTIK CA 3556HF (Snapcure Ag Acrylate)

- LOCTITE ABLESTIK 56 C (2K RT Cure)

- LOCTITE ABLESTIK JM 7000 ( very high T, >300°C)

Benefits of LOCTITE® ECCOBOND:

- Cure times of less than two minutes

- Silver or nickel filled systems

- In-line processing capability

- For exceptionally high throughput

- Suitable for applications with large differences

of coefficients of thermal expansion (CTE) between substrates - Suitable for flip-chip interconnects with tight pitch,

where electrical conductivity is desired in only one direction - Low viscosity and fast flow

- Excellent wettability and adhesion

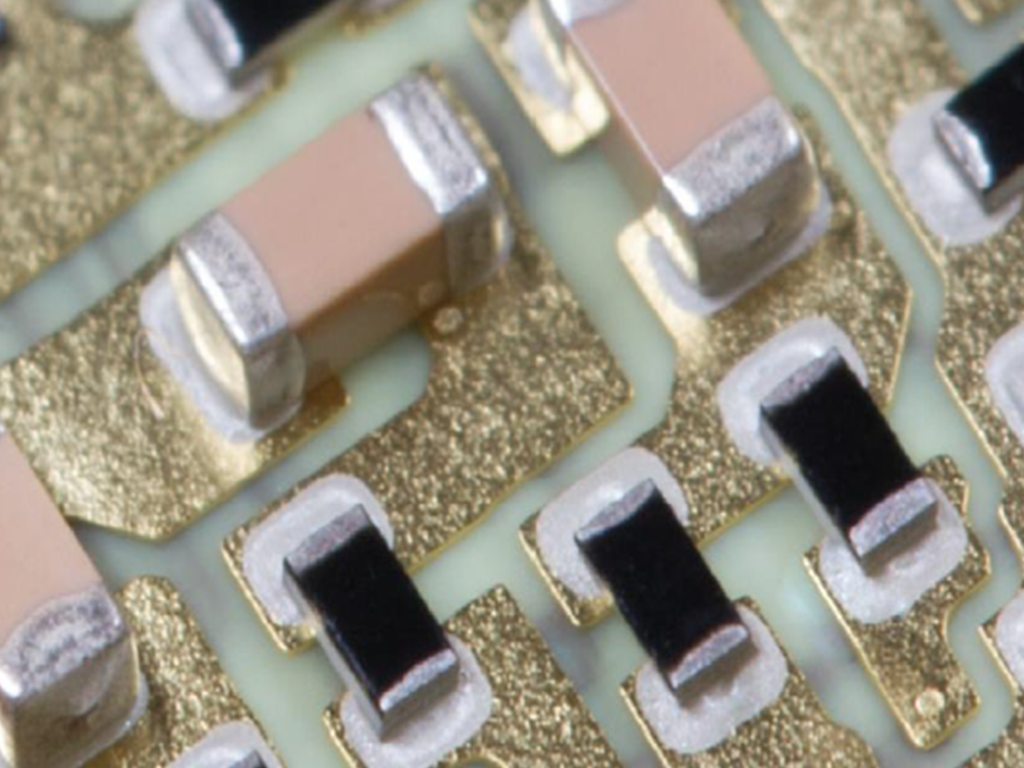

Surface mount adhesives

Surface mount adhesives (SMA) were developed to fix electronic components on the PCB before the soldering process. They are preferably used for wave soldering and also to achieve additional adhesion during reflow soldering. The products are based on 1K thermosetting epoxies. The material ensures sufficient adhesion even in the uncured state.

We offer printable as well as dispensable products.

Our recommendation

- LOCTITE® 3609 (REACH compliant)

- LOCTITE® 3621 (jetting application)

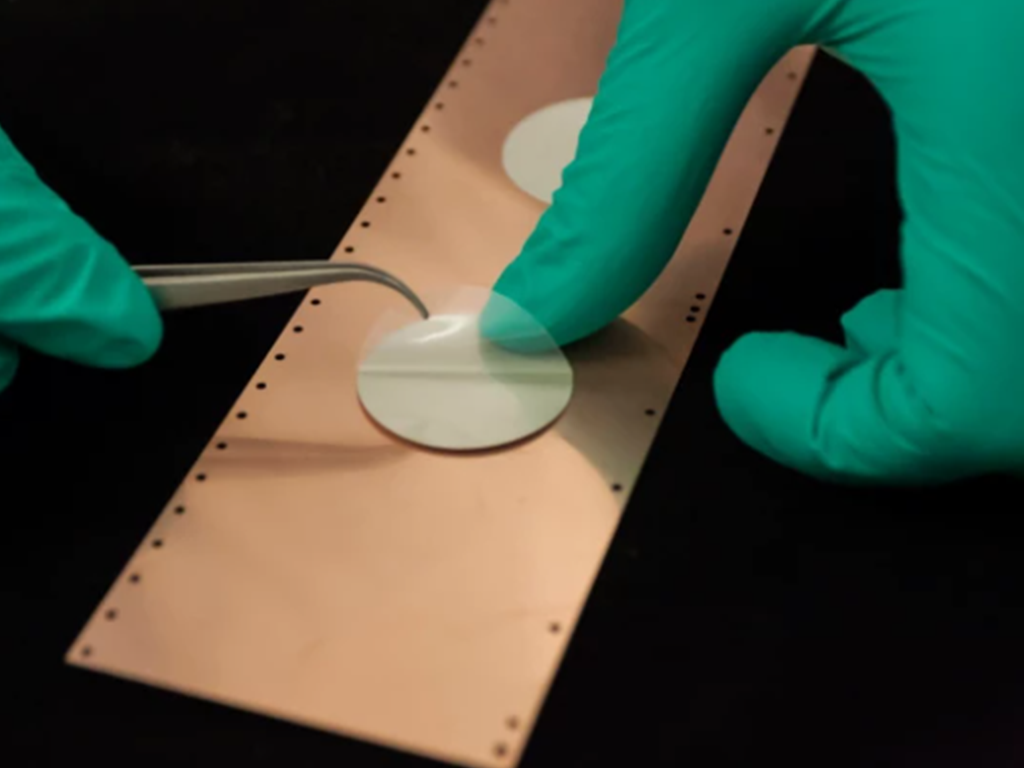

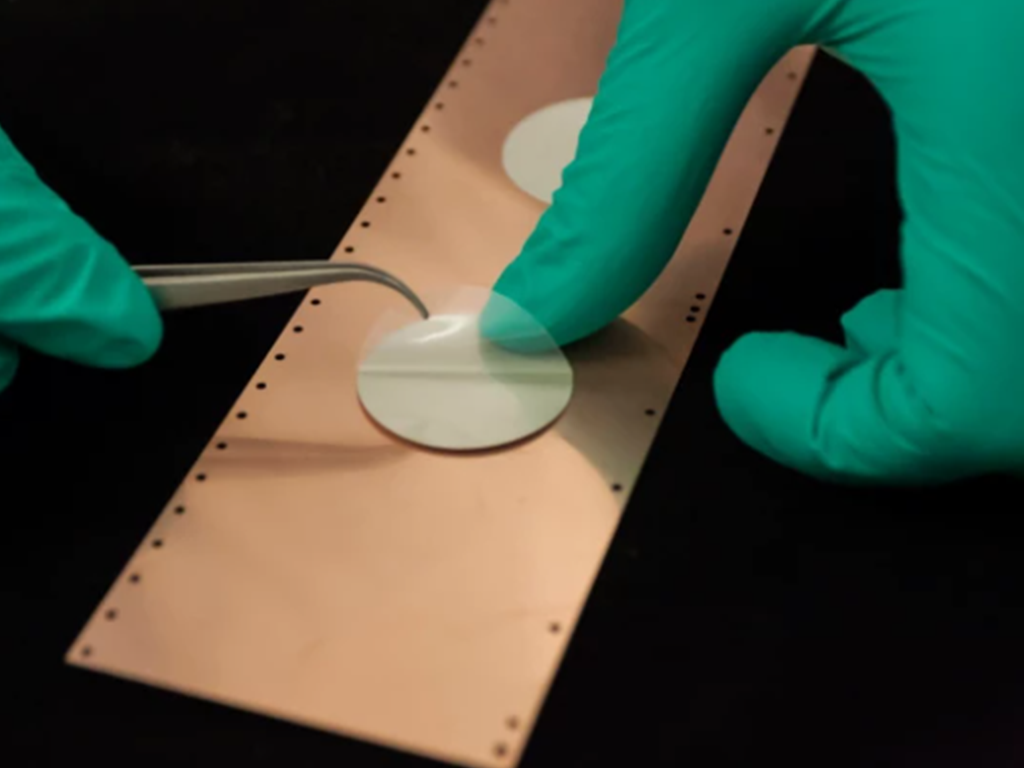

Adhesive films

With ever-smaller components combined with ever-higher functionality and growing performance requirements, thermal management is a critical factor. Henkel’s assembly films not only offer best-in-class properties in terms of electrical, thermal and mechanical performance, but also reduce overall assembly costs by eliminating the need for costly warehousing or further processing at conversion companies.

Henkel’s assembly films are proven solutions for the most demanding applications requiring the highest reliability. Henkel offers customized, pre-cut film blanks that are precisely matched to complex PCB shapes and patterns. This ensures an exact amount of void-free adhesive with controlled adhesive joint thickness in a given area.

Features and benefits

- Epoxy based film

- Uniform film thickness

- Supplied in “dry” form

- Very easy to process

- Available in sheet form or

cut to size- Electrically conductive

- Electrically non-conductive

- Thermally conductive

- Thermally non-conductive

Our recommendations:

- LOCTITE ABLESTIK CF 3350 (electrically conductive)

- LOCTITE ABLESTIK 561 (thermally conductive)

- LOCTITE® 550 (non-conductive)

Talk to our Experts for electronic adhesives

Your experts for Germany

Reno Wirnitzer

M +49 151 14824561

r.wirnitzer@bm-chemie.de

Rainer Fausel

M +49 151 18815644

r.fausel@bm-chemie.de

Contact formular